-About-

Shape Memery Alloy Materials

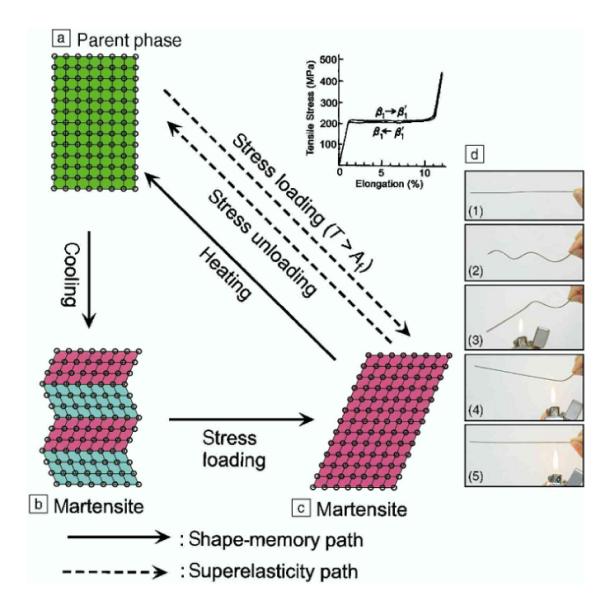

- Superelastic Effect (SE):The SE is the ability of Shape Memory Alloys to fully recover from significant deformation, exceeding the capabilities of conventional materials and alloys. This makes SMA ideal for use in implantable medical devices.

- Shape Memory Effect (SME) :The SME allows Shape Memory Alloys to “remember” their original shape and return to it when overheated, enabling unique functionalities in various industries such as automotive,electronics and medical.

- A complex manipulation process that starts from nickel and titanium:Shape Memory Alloys (SMA) are a family of high-tech materials that begin with the basic elements of nickel and titanium. The addition of other elements can dramatically alter the final properties, making it suitable for a wide range of applications. The journey from raw materials to finished product involves a multitude of options, from melting techniques to ingot sizes, and from hot to cold conversion. Every processing step has an impact on the properties and performance of the final component, whether it’s a wire for electrical actuators, a spring for thermostats, or a medical implant. The most critical step is the final thermomechanical processing, also known as training or shape setting, where the properties of the material are set and fine-tuned to meet the specific needs of the application. At the cutting-edge of technology, SMA is a truly remarkable material with limitless possibilities.

Endless possibilities are enabled by the material's advanced properties.

Shape Memory Alloys (SMA) offer a world of possibilities with their unique combination of size, shape, and geometry versatility. The Shape Memory Effect (SME) is activated by a change in the component’s lattice structure, transforming from martensite to austenite and resulting in a change in shape and mechanical properties. These materials are revolutionizing the automotive, medical, and electronics industries with their lightweight, compact, energy-efficient, and noiseless electrical actuators.

Additionally, the Superelastic Effect (SE) is making waves in the medical field, where it is being used in implantable devices such as stents and aortic valves, thanks to its ability to fully recover significant deformation beyond that of conventional materials. SMA truly is a material of the future, changing the way we live and work.

Temperature and stress causes shift in materials crystalline structure between these two phases which lead to Shape Memory Effect.

![]()

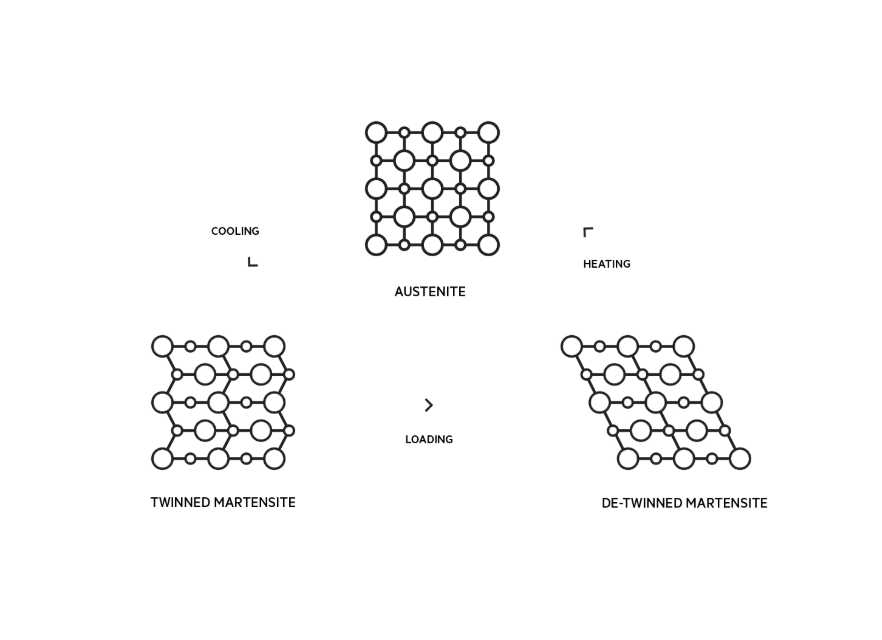

3 Crystal Structures

The three different crystal structures in Shape Memory Alloys are Martensite, Austenite, and twinned Martensite.

- Martensite is a highly distorted, low-temperature crystal structure.

- Austenite is a high-temperature, stable crystal structure.

- Twinned martensite is a partially transformed mixture of Martensite and Austenite.

2 Phases

The phase transition from Martensite (Low Temperature Phase) to Austenite (High Temperature phase) in SMAs occurs due to changes in temperature or stress, causing the crystal structure to change from a distorted Martensite form to a more stable Austenite form.

This results in recovery of the original shape.

Application Solutions

![]()

Application of SMA Materials in Biomedical Field

TIN alloy has good biocompatibility. After being implanted in the human body, its shape memory effect is used to activate its own superelastic principle by the action of body temperature. There are many medical examples, such as thrombus filters, spinal rods, dental bridge wires, cerebral aneurysm clips, bone plates, intracranial needles, artificial joints, contraceptive devices, heart repair components, micro pumps for artificial kidneys, interventional guide wires and surgical sutures, various intracavitary stents, etc.

Application of SMA Materials in the Automotive Field

SMA has a wide range of application prospects in the automotive industry. For example, in automobile engines, nickel-titanium shape memory alloy can be used to make valves, piston rings and transmission parts, providing shape memory and superelastic properties at high temperatures. In addition, it can also be used to make car seats, suspension systems and brake systems, providing comfort and safety.

Application of SMA Materials in 3C Field

SMA materials are widely used in consumer electronics. For example, Huawei, Apple, Xiaomi and other smartphone brands have all launched optical image stabilization motors for mobile phone lenses made of SMA materials, leading the technological innovation of the mobile phone industry.

SMA materials are also commonly used in consumer electronics products such as vibration motors in flat displays and tactile motors in VR products. They are widely used in smartphones, tablets, wearable devices, VR/AR and other industries.

Application of SMA Materials in Aerospace Field

SMA connectors are widely used in aerospace products due to their miniaturization, high frequency and high performance. They can maintain stable connections under extreme temperatures and mechanical stresses, and are suitable for high-performance RF coaxial connections with a transmission frequency range of up to 18GHz or higher.

SMA materials integrate sensing and driving, and can achieve external work by changing the ambient temperature. Therefore, intelligent drivers and shock absorbers can be made to achieve active monitoring of material damage.

Other Applications (Medical)

![]()

SMA shape memory alloy is called "living alloy". It has the ability to remember or retain its original shape under specific external excitation conditions such as thermal or magnetic excitation. Compared with traditional actuators based on electromagnetic, pneumatic and hydraulic principles, it has a simple structure, a high power-to-weight ratio and no noise (electromagnetic noise).

Medical and health applications:

TIN alloy has good biocompatibility. After being implanted in the human body, its shape memory effect is used to activate its own superelastic principle by the action of body temperature. There are many medical examples, such as thrombus filters, spinal rods, dental bridge wires, cerebral aneurysm clips, bone plates, intracranial needles, artificial joints, contraceptive devices, heart repair components, micro pumps for artificial kidneys, interventional guide wires and surgical sutures, various intracavitary stents, etc. The most classic application

(1) Bone plates for bone fractures can not only fix two broken bones, but also generate compression force in the process of restoring their original shape, forcing the broken bones to join together.

(2) Thrombus filters. After being straightened and implanted in the vein, the filter will gradually return to a mesh shape, thereby preventing 95% of blood clots from flowing to the heart and lungs.

(3) Artificial heart is a more complex organ. The muscle fibers made of memory alloy cooperate with the elastic film ventricle to imitate the contraction movement of the ventricle.

Get In Touch

Need more information or have questions? Contact us today, and our expert team will provide you with personalized support and solutions.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)